Process stability is the key to product quality.

We attach great importance to the control of all processes and quality.

We are committed to meeting the needs of our customers.

Process stability is the key to product quality. We attach great importance to the control of all processes and quality. We are committed to meeting the needs of our customers.

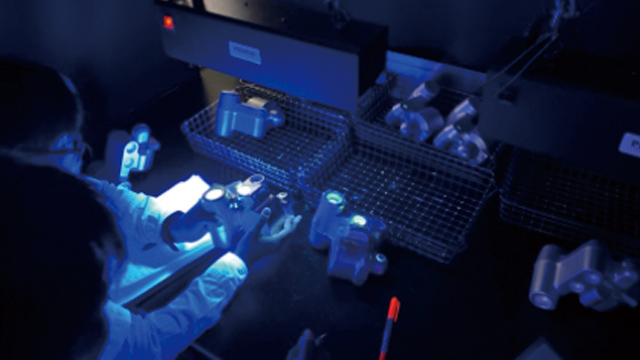

Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI) is an inspection method that uses a specific dye or fluorescent light to detect defects on the surface of an object. It is a non-destructive inspection method that uses the capillary action of penetrating fluid to penetrate interruptions or cracks in the surface of the object being inspected to inspect or identify defects. According to the principle of permeation, when the surface of a product is discontinuous (cracks, seams, overlaps, cold interlayers, shrinkage or insoluble, etc.), the penetrating fluid will penetrate the interstices with openings in the surface. After the penetrating fluid of the surface has been cleaned, the penetrating fluid remains in the interstices and can be clearly seen under a specific light source.

Eddy Current Fracture Detection & EC Current Value Inspection Station

Source: GE, USA

Three-dimensional measuring machine

The three-coordinate measuring machine, also known as a three-dimensional measuring machine, is derived from the English term "Coordinate Measuring Machine", abbreviated as "CMM". It is a device that measures the geometry of the object to be measured by means of a probe and discrete points on the surface of the object.

Hardness Testing